The Basics of Damascus Knife Patterns

Posted by Best.Buy. Damascus1 on

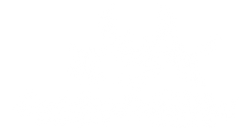

The immense popularity of Damascus knives in recent years is due to their beauty and attractiveness, thanks to their exquisite patterns. Each Damascus knife has a distinctive quality due to the various and unique Damascus steel patterns on the blade. In addition to this, the Damascus steel knife has long been sought due to its hardness, flexibility, and ability to maintain an edge.

Due to its useful features, a Damascus knife has been used for outdoor activities and in the kitchen. Whether you already have one or are intending to buy a knife made of Damascus steel, learn about the damascus steel pattern that greatly adds to its visual interest.

There is more to the finely detailed patterns you see on Damascus blades than the eye can see. Aside from a distinctively aesthetic touch, they also have practical advantages that make them more than just lovely works of art.

A procedure known as "pattern welding" creates these wavy patterns on a Damascus knife. It is a special technique that entails forge-welding parts made of different compositions of iron and steel.

Understanding Pattern Welding

Pattern welding is a unique process of making knives and swords using metals with different chemical compositions and then twisting them to produce a distinctive wavy pattern. The use of pattern welding dates back to the 2nd century AD. The method was developed in line with the demands for stronger, tougher knife blades, which could not be produced by traditional iron smelting.

Knifemakers select two or more distinct steel sheets that are used to create an intricate, stunning pattern. To make billets, the steel is stacked on top of one another. Then, after being heated and hammered, these billets are twisted and folded together.

The steel is hardened to make a structure by quenching after the billets have been folded and hammered adequately. For shaping the steel, it’s hammered, lengthened, and flattened.

The blade is then treated with the annealing and etching procedures, which involve immersing it in an acid that reacts differently with the varied steels to produce a stunning, distinctive Damascus pattern.

The heat treatment changes the color of steel. The varied colors appear due to the steels' varying degrees of corrosion resistance reacting to heat in different ways, revealing lighter or darker colors, accordingly.

As mentioned above, the various patterns on pattern-welded steel are the result of combining several steels during forging. The main purpose of this steel-blending was to take advantage of the various properties that these steels possessed. Similar to ancient Damascus steel, modern Damascus steel manufactures its products mostly through pattern welding.

Damascus patterns are only there for decorative purposes.

Although these patterns aren’t a functional feature, they can reveal a lot about the quality of a Damascus knife. Knives manufactured from Damascus steel using pattern welding are strong and have excellent edge retention.

Damascus steel has patterns that go deeper than the surface. The marks on the blade will remain no matter how many times you scratch it, even if they might no longer be visible to the human eye. This helps to identify fakes from real Damascus steel blades.

Due to its forging process, a Damascus knife is expensive and beautiful. Even though it won't offer much in the way of performance, its aesthetic value makes it worthwhile.